In capacitor research, much effort has been focused on development of high energy density devices. It’s easy to see why. The need for efficient, high-performance materials for electrical energy storage has been growing in parallel with the ever-increasing demand for electrical energy in mobile applications. Along the way dielectric capacitors, which comprise an insulating material sandwiched between two conducting metal plates, have become key components of portable electronics, computing systems and electric vehicles. One hurdle preventing even faster growth is that in contrast to batteries, which offer high storage capacity but slow delivery of energy, capacitors provide fast delivery but poor storage capacity.

To close that gap the current strategy has been to increase the specific surface area of the electrodes, employing nanomaterials with large specific surface areas, which promise to deliver electrical energy storage devices with a high energy density. Unfortunately, these approach strategies to enhance the performance of dielectric capacitors has not been able to simultaneously achieve large capacitance and high breakdown voltage.

Recently a group of researchers at the University of Delaware (UD) and the Chinese Academy of Sciences demonstrated how such limitations can be overcome. In their paper, “Dielectric Capacitors with Three-Dimensional Nanoscale Interdigital Electrodes for Energy Storage,” (co-authored by Fangming Han, Guowen Meng, Fei Zhou, Li Song, Xinhua Li, Xiaoye Hu, Xiaoguang Zhu, Bing Wu and Bingqing Wei) published in Science Advances, an online-only journal of the American Association for the Advancement of Science (AAAS), the researchers discuss how they used nanotechnology to design electrodes that address the low ability of dielectric capacitors to store energy.

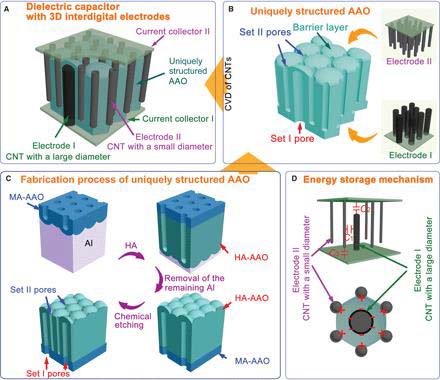

To accomplish their goal the researchers embedded carbon nanotubes in a uniquely designed and structured 3D architecture. They fabricated a unique nanoporous—meaning the size of the pores is generally 100 nanometers or smaller – anodic aluminum oxide (AAO) membrane with two sets of interdigitated electrodes (here, to understand the concept you should think of interwoven fingers between two hands with gloves, thus increasing the ability of the capacitor to store an electrical charge). The researchers deposited carbon nanotubes in both sets of pores inside the AAO membrane, realizing a dielectric capacitor with 3D nanoscale interdigital electrodes. The large specific surface area of the AAO membrane contributes to the enhanced capacitance.

Bingqing Wei, professor of mechanical engineering at UD noted that with this approach the researchers achieved an energy density of about two watt-hours per kilogram, which is significantly higher than that of other dielectric capacitor structures thus far reported and is close to the value of a supercapacitor, which means it has promising potential in high-density electrical energy storage for various applications.

The newly structured capacitor was fabricated by Chemical Vapor Deposition (CVD) growth of carbon nanotubes (CNTs) in the two sets of nanopores of the uniquely structured AAO membrane. The nanoporous AAO is formed by electrochemical oxidation of aluminum in acidic solutions (see Fig. 1, below)

Figure. 1 Schematic depiction of the structure, fabrication process, and energy storage mechanism of the newly developed dielectric capacitor. (A) Dielectric capacitor with 3D interdigital electrode. (B) Breakdown structure of the dielectric capacitor. (C) Fabrication process of the uniquely structured AAO membrane. (D) Schematic depiction of the energy storage mechanism of a unit cell in the newly structured dielectric capacitor from side view (top) and top view (bottom). (Source: University of Delaware).

Another significant feature of the capacitors is that the unique new three-dimensional nanoscale electrode also offers high voltage breakdown, via the use of hemispheric barrier layers. Simply put, this means that the integrated dielectric material (alumina, Al2O3) does not easily fail in its intended function as an insulator.

In summary a capacitance density of about 47 μF/cm2 for 6-μm-thick HA-AAO was achieved and a breakdown voltage of about 15 V was observed, the researchers reported. Wei et al. anticipate that their work will open up a new window to designing 3D nanoarchitectural electrodes for various energy storage applications.

Also working to find a single dielectric material able to maximize permittivity, breakdown strength, energy density and energy extraction efficiency Joseph Perry, professor in the School of Chemistry and Biochemistry at Georgia Tech’s Center for Organic Photonics and Electronics (COPE)and his colleagues reported in July in the journal Advanced Energy Materials that they have developed a new capacitor dielectric material said to provide an electrical energy storage capacity rivaling certain batteries, with both a high energy density and high power density.

Using a hybrid silica sol-gel material and self-assembled monolayers of a common fatty acid (octylphosphonic acid, which provides insulating properties), the researchers demonstrated maximum extractable energy densities up to 40 joules per cubic centimeter, an energy extraction efficiency of 72 percent at a field strength of 830 volts per micron, and a power density of 520 watts per cubic centimeter. This performance exceeds that of conventional electrolytic capacitors and thin-film lithium ion batteries, though it doesn’t match the lithium ion battery formats commonly used in electronic devices and vehicles.

By depositing a nanoscale self-assembled monolayer of n-octylphosphonic acid less than a nanometer thick on top of the hybrid sol-gel, the monolayer serves as an insulating layer. Consequently the bilayer structure is said to block the injection of electrons into the sol-gel material, providing low leakage current and high breakdown strength.

If the material can be scaled up from laboratory samples, devices made from it could surpass traditional electrolytic capacitors for applications in electromagnetic propulsion, electric vehicles and defibrillators, for example. Capacitors often complement batteries in these applications because they can provide large amounts of current quickly. If the scale-up is successful, Perry expects to commercialize the material through a startup company or SBIR (Small Business Innovations Research) project.